- Home

- Markets

- About

- Services

- Project

- Applications

- Plant Technology

- Blog

- Contact Us

Innovation in Carbonated Soft Drinks & Bottled Water for

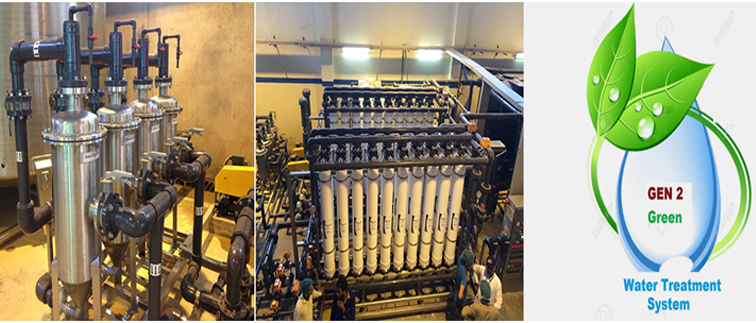

Gen2Green & Green Field WTP – Projects

As per Pepsi Cola Bottlers (G2G Process Design Criteria Rev-1) AND Coca

Cola Bottlers (TCCC ve ICCC Water Standards Specification, BP-SP-184)

"Water is going to emerge as a real challenging issue for the food and beverage sector,"

According to the beverage giants, the new system meets or exceeds CSD/drinking water standards. Our company Kontel Technologies USA Inc. has successfully completed the design, supply, installation and commissioning (Turnkey Projects) of the Gen2Green and Greenfield WTP-Projects as per PepsiCo & COKE standard process design Criteria’s.

Salts and minerals (TDS) in drinking water plays a vital role in drinking water but up to a certain limit. Excess concentration of salts and minerals make the water saline and not fit to human consumption in terms of taste and health. Raw water also contains some toxic and hazardous material in raw form and cannot be removed by any chemical process. GEN2GREEN & GREENFIELD WTP are the only a physical process to eliminate up to 97% of salts along with almost all hazardous, toxic and biological continuations. All soft drinks, juices and fruit flavor based drinks are a combination of ACID SUGAR combination and only GEN2GREEN & GREENFIELD WTP water can be the true outcome of the basic recipe Carbonated. GEN2GREEN & GREENFIELD WTP will provide best water for your (object) CSD & Water production with new innovation like safest water for CSD drinks.

| Contaminant | OTL |

|---|---|

| Bromate | 5.0 ppb |

| Chlorate | 200 ppb |

| N-Nitrosodimethylamine | 0.01 ppb |

| Perchlorate | 5.0 ppb |

| Perfluorooctanoic Acid | 0.06 ppb |

• Flavor segment of Citrus Based CSD drink like 7up, Miranda will more improve like real fruit.

• More efficiency of CO2 absorption to make best taste of drink even till the end of every drink (Bottle)

• Maximum yield recovery through smooth production interlink with Brix improvement through ultra pure water.

• More clear even transparent Syrup of CSD drink with pleasant taste and beautiful bubbles of CO2.

• Trouble Free performance of filler due to ultra pure water with minimum level of Filler’s material deterioration and smooth filling of every bottle.

• Efficiency improvement at Carbo Cooler process for energy conservation.

• Long lasting total micro free Drink through efficient treatment by UF system, and many more

Everyone who sells Coca-Cola fountain drinks uses the same syrup and fountain machines but WTP based Out lets tastes better. Learn Outlets impossible innovation. If you’ve ever bought a Coca-Cola from a gas station soda fountain you’ve probably noticed it doesn’t taste the same as Coca-Cola from WTP Based Outlets. You might have noticed that a Coke from other restaurants without WTP also don’t taste the same. If you look at how Coca-Cola controls every aspect from the syrup to the fountain machine you probably wonder why it doesn’t taste exactly the same everywhere. If you are like most people, you agree Coca-Cola from WTP Based Outlets tastes better than anywhere else. It’s hard to describe the exact way it tastes better but it certainly does. Moreover, it consistently tastes better at every WTP Based Outlets.

One of steps of Predictive Innovation® is to list the objects for a scenario.

In the scenario of making Coca-Cola fountain drinks the objects are:

• water

• syrup

• CO2

• ratio of ingredients

• mix of ingredients

• temperature

• Rotation ………………….How to change a BIB (Bag-in-Box)

• Refrigeration …………….Ice Cooled/Mechanical/Remote Refrigeration

• Carbonation ……………..Change an empty CO2 Cylinder

• Presentation …………….Soft drink from disperser always clean

• Sensation ……………….The unique refreshing taste depends on Water Quality

Of all those objects, WTP Based Outlets can only control two of them. The rest of the objects are controlled by Coca-Cola or the customers. The two things WTP Based Outlets can control are their water and the freshness of the syrup. CO2 is a standard gas that makes the drink fizzy. The ratio of ingredients and the mix of ingredients are controlled by the fountain machine and that is set by Coca-Cola. Customers can change the temperature by adding ice. Water and freshness of syrup are the secret of WTP Based Outlets fountain drink innovation.

Water is 85% of a fountain drink. If the water is bad you will taste it. Like everything else without WTP based Outlets does, they meticulously control their water. Each restaurant has a reverse osmosis filter providing the best water available. This not only makes the Coca-Cola taste better it also makes their coffee taste better. The water you get at WTP Based Outlets is the cleanest anywhere and that is the #1 reason their fountain drinks taste the best.

Most Coke retailers get their syrup in a bag box. These bag boxes are small and allow a retailer to provide Coke with a minimal investment. Several Outlets sells a lot of Coke. They sell so much coke that they don’t need to buy the syrup in the small bag box. Most Outlets / restaurants can get syrup delivered from a tanker truck and store it in a stainless steel cylinder. Because they sell a lot it doesn’t sit around as long. So the Coke syrup at Outlets is fresher than their competitors. Fresher syrup makes better tasting fountain drinks. These Outlets also controls freshness by cleaning everything daily. Letting syrup sit in hoses and machines allows it to chemically degrade and for bacteria to grow. Keeping everything clean also keeps it fresh and tasting good. So even though all their competitors have the same basic ingredients that are required to be put together the exact same way, WTO-RO Based Outlets found a way to innovate and provide a better product.